Injection Molding

The Injection Mold experts at Globalink Manufacturing Solutions have vast experience fabricating quality Medical Molded components utilizing Plastic Injection Molding processes.

Plastic Injection Molding is a low cost solution to projects that demand moderate to large quantities. Our goal is to help you develop and produce Injection Molded plastic parts that fit and work while saving you time and money.

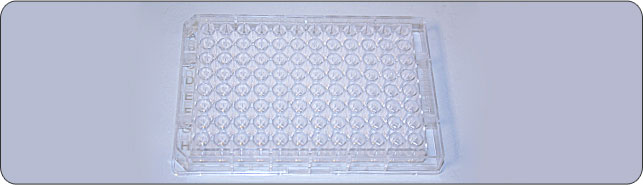

We produce a wide range of Plastic Injection Molded components. Our 18,000 – 20,000 ton machines can handle everything from very basic single cavity molds to highly complex multi-cavity tooling that requires state-of-the-art equipment, capabilities, and processes.

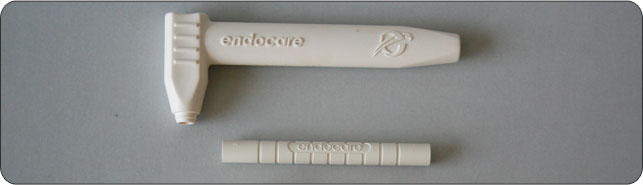

We offer highly specialized processes to fit the demands of your project. For instance, some projects lend themselves to Insert Molding, during which the plastic is molded around a metal or plastic part that has been placed in the mold prior to the start of the injection molding process. Others may require the specialized process of Over Molding where we take one plastic component and then mold another plastic housing around it. Over molding often eliminates assembly operations by combining parts in the actual injection molding process.

Whatever your need is, custom plastic injection molding, insert molding, over molding, ultrasonic plastic welding, pad printing, screen printing, or plastic part assembly, we can meet your needs. Call us today!